Introduce

About SHC - Company Overview

Welcome to SHC Industrial Products Company Limited – where creativity and quality meet to create outstanding products.

With many years of experience in the industry, SHC Dong Thap is proud to be the ideal partner for all your packaging needs.

We are committed to providing customers with diverse and effective packaging solutions. Our manufacturing process is conducted by a team of skilled professionals, using advanced technology to ensure each product meets the highest quality standards.

Compatibility with a wide range of products and customization are our strengths. We understand that each customer has unique requirements, and we pride ourselves on being able to meet every challenge with flexibility and creativity.

Please join us to create unique packaging solutions that are environmentally friendly and bring added value to your products. We not only provide cartons, but are also a reliable partner on your journey to success.

SHC's Vision

"Our vision is to become the leading packaging partner in Vietnam and the world, where creativity and quality blend to create excellent packaging solutions that highlight value and beauty. of every product."

Grandfather YANG WEIBAO – General Director of the company

SHC's Mission

"Providing convenient packaging solutions, contributing to improving productivity and operational capabilities for customers."

SHC's Core Values

Integrity: Always act transparently, correctly, for long-term benefits.

Responsibility: Do it with dedication and sincerity.

Effective: Focus on real results – accurate, optimal, on time.

Team: Unity, coordination, and consensus for a common goal.

Renew: Always welcome challenges, creativity from difference.

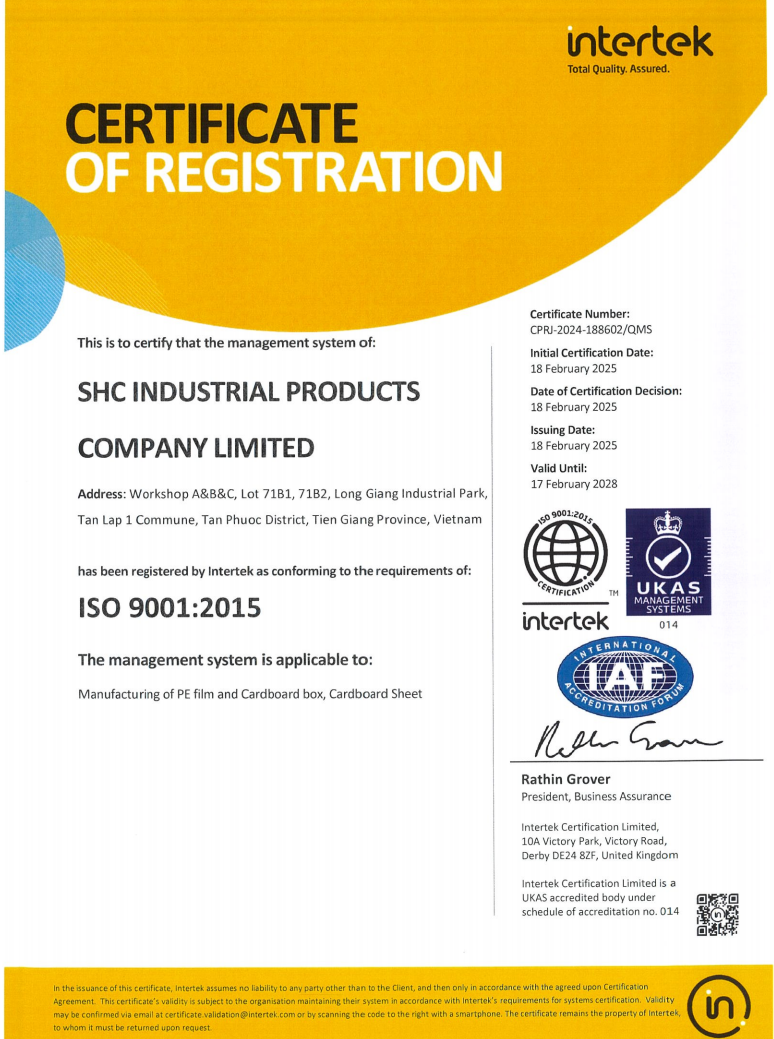

Certification - International Standards

Possessing an international certification system is SHC's commitment to maintaining quality, protecting the environment, ensuring labor safety and fulfilling social responsibility.

ISO 0

Quality management system

ISO 0

Environmental management

ISO 0

Occupational Safety & Health

SA0

Social responsibility

FSC

Legal timber supply chain certification

SHC scale

With a total area of 18,296.5 m², the factory is systematically invested and scientifically planned with 2 large workshops and a modern executive office area. The entire production line is digitalized, optimized for operation and synchronized between stages.

Factory 1: 6,000 m²

Factory 2: 7,000 m²

Office: over 320 m²

Equipped with Flexo printing machines, digital inkjet printing machines, corrugated carton lines, die-cutting machines, gluing machines, slotting machines... we have achieved impressive capacity: Carton sheets up to 100,000 m² / 8 hours. Carton boxes up to 200,000 boxes / day. From standard orders to special designs, products are processed quickly, accurately and synchronously, meeting the schedule and quality requirements of customers.

MODERN MACHINERY SYSTEM

2-color Flexo horizontal printing machine

The latest Flexo horizontal printing machine can print from 1 to 5 colors with fast speed, automatic adjustment, high precision, with functions such as slotting, corner cutting, creasing or round die cutting. The design ensures safety and convenience for the operator.

8-head digital inkjet printer

Quickly print from electronic design files without making copies, saving time and money. Sharp images, vivid colors, suitable for printing logos, barcodes, QR codes with flexible customized content according to orders.

64 nozzle digital inkjet printer

Outstanding performance, 5-6 times faster than 8-head machine, reaching 150-200m/min. Ideal for large-scale production lines, maintaining stable quality, no ink smudging, no image blurring. Optimize productivity, shorten order completion time.

5 color Flexo printing machine combined with round die cutting roller

5-color printing is sharp and uniform, meeting high aesthetic standards, combined with a round die-cutting roller, printing and die-cutting at the same time, shortening production time, automatically aligning, reducing errors, improving accuracy. Suitable for mass packaging production, saving labor costs.

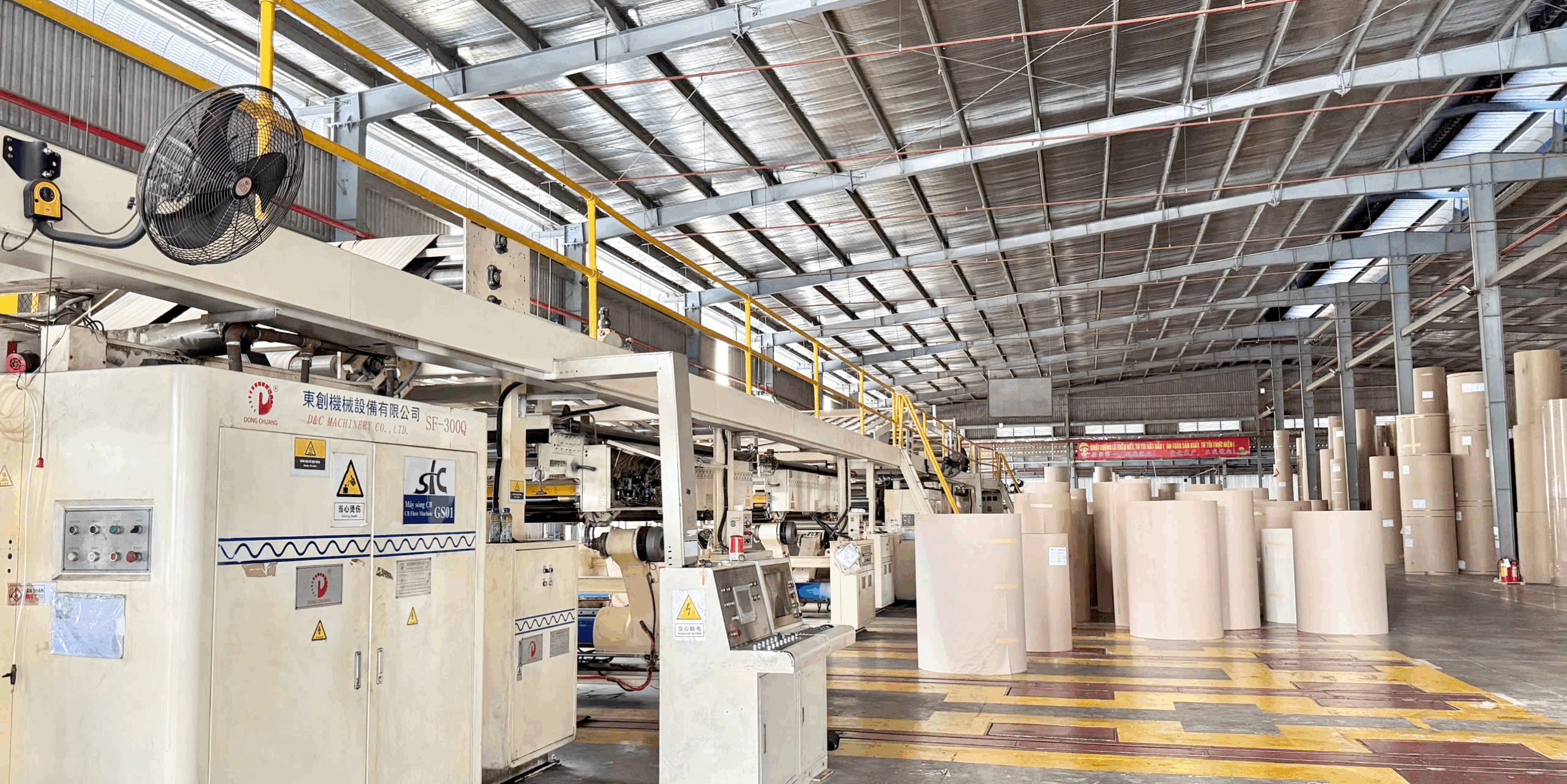

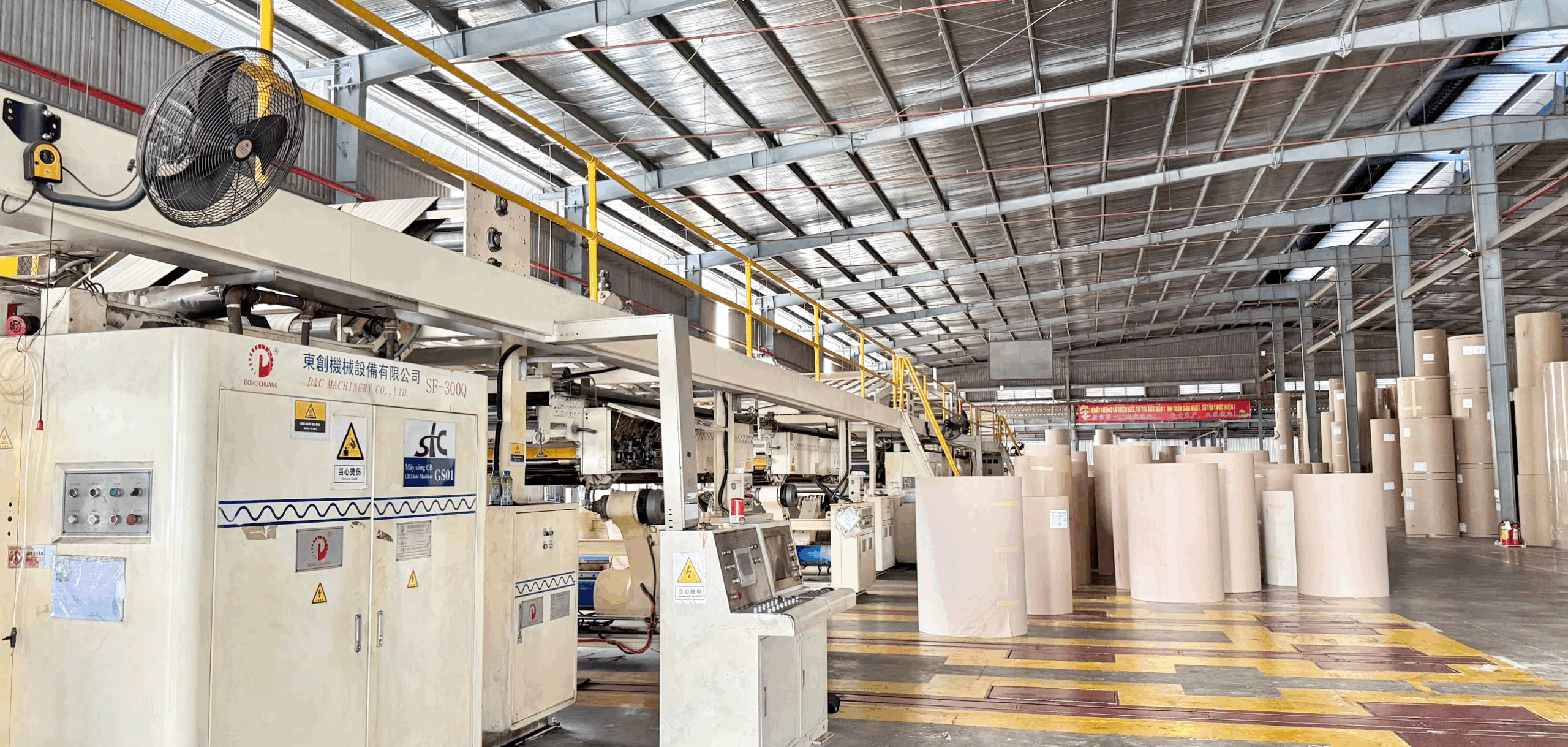

Corrugated cardboard production line

Production line of 3-layer and 5-layer corrugated paper with maximum width of 2.5m, various types of single waves such as A, B, C, E and double waves AB, BC, BE.

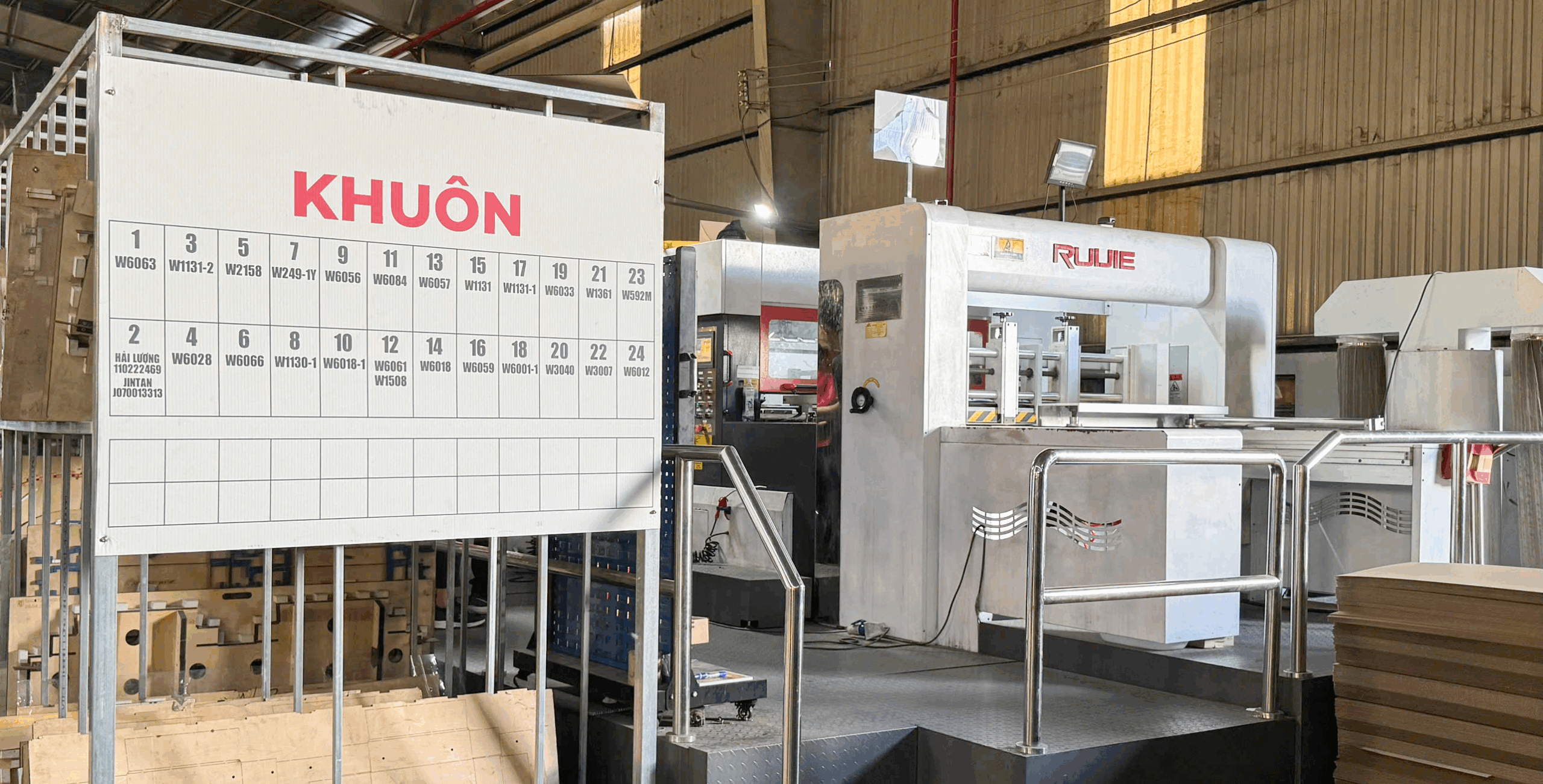

Flat die cutting machine

Used in small-scale carton manufacturing companies, the machine runs fast, is precise, easy to operate, and can cut many types of boxes such as yin-yang boxes, round liners, etc.

Automatic Filling Machine

Grooving, cutting, folding lines for 3-5 layer carton boxes, automatic size adjustment, suitable for many box specifications, high speed, stable operation, maximum error reduction. Suitable for closed lid boxes, overlapping lid boxes, die-cut boxes or flexo printing boxes.

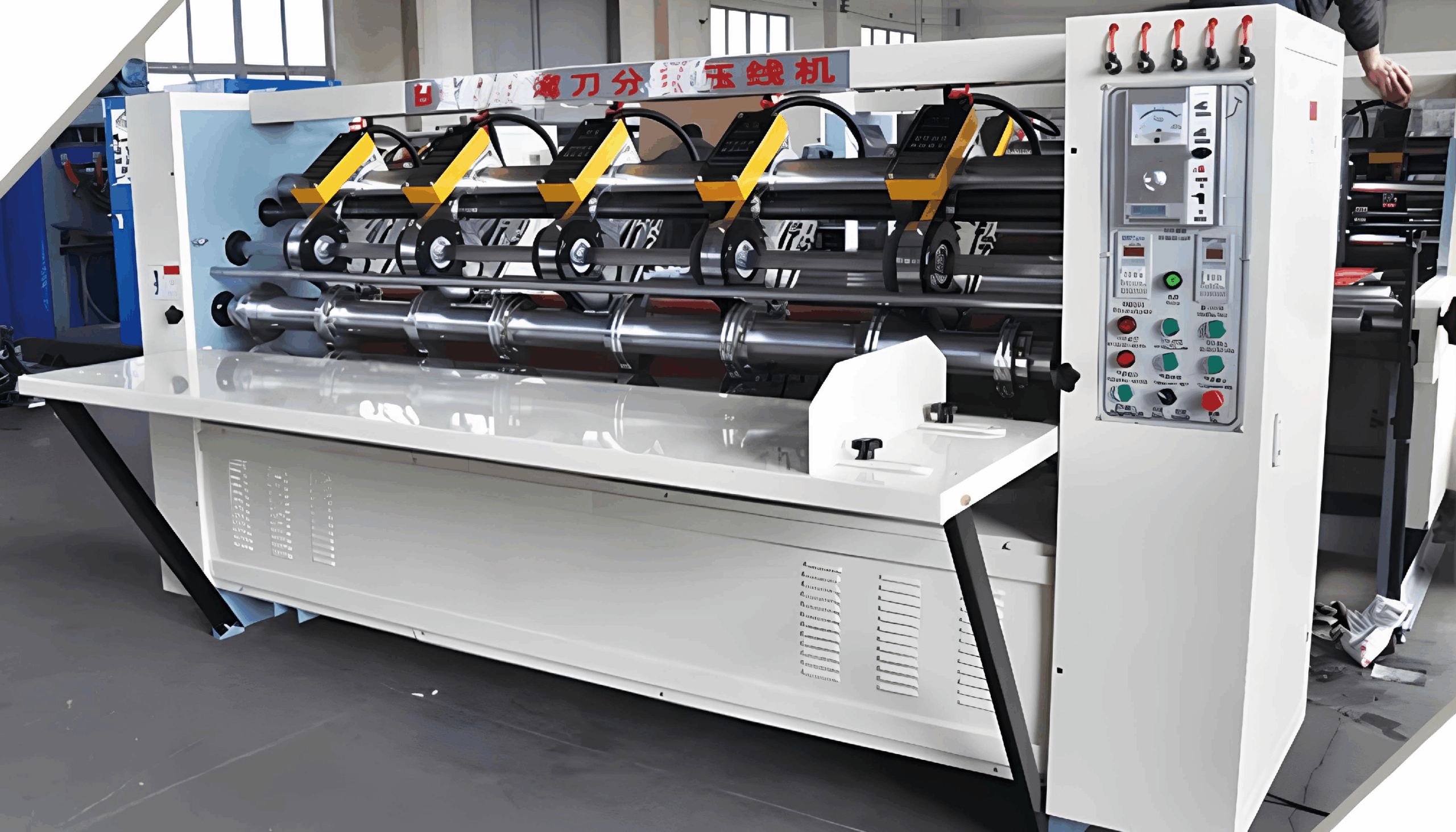

Creasing and dividing machine

The knife specifications can be adjusted and completely controlled by computer in less than 1 minute. The machine automatically runs according to the line speed, connected to the production management system to ensure line synchronization.

Automatic stapler

U-shaped stapler is used for many different types of paper, is an important equipment in modern carton production, ensuring sharp, precise products. Easy to process quickly for large orders and on demand.

Automatic gluing machine

Used in the final stage of the packaging production process, the gluing machine (or tape gluing machine) helps complete carton packaging.

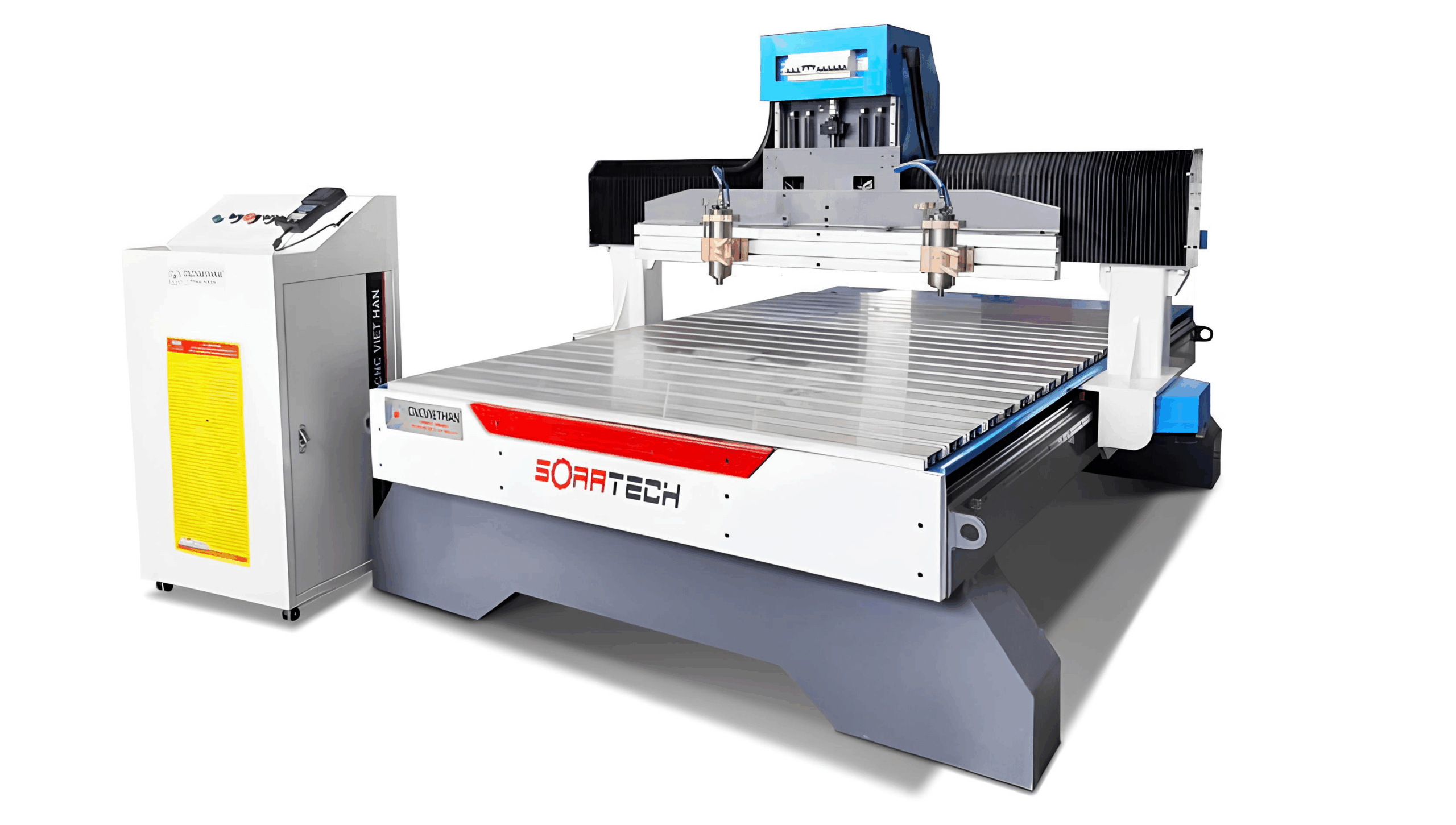

CNC wood cutting machine

Pre-programmed to cut, engrave, drill, and mill wood precisely according to design drawings (CAD/CAM), allowing for cutting complex shapes and small details regularly, working continuously and automating many stages.

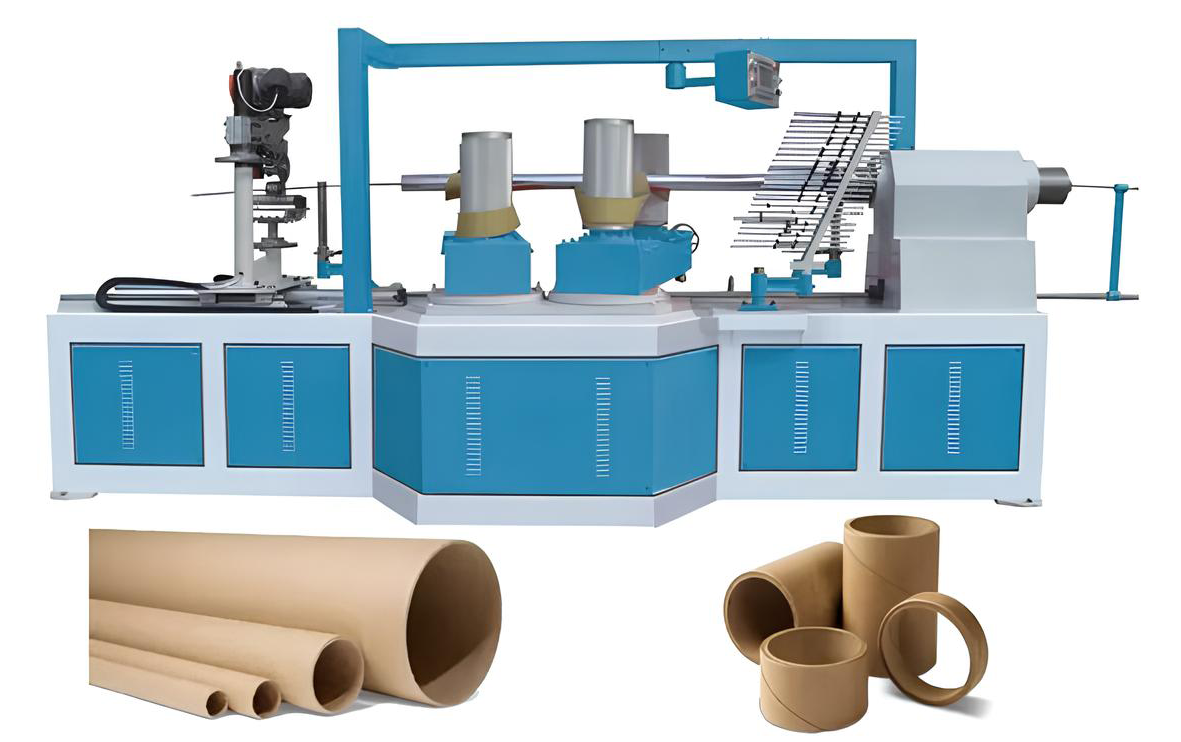

CA-100 Automatic Spiral Paper Tube Making Machine

Medium size paper core tube making machine, automatic PLC control via touch screen. Diverse cutting system from 500-5000mm, can customize components such as motor, inverter, PLC as required.

Stretch film machine PE stretch film machine CL-65/80/120/80CH-2000

Production of multi-layer PE film (2 layers, 3 layers), flexible from basic to high performance film, using high-speed, precise thickness control technology, suitable for many industrial packaging applications.